| Facilities |

Images |

|

Universal Tribometer:

Rtec instruments

UT measures friction, wear and lubrication properties of material using rotating and reciprocating sliding contact test methods. This machine performs multiple testing: pin on disc, ball on disc, Fretting test and High temperature reciprocating test.

|

S.No

|

Parameters

|

|

1.

|

Load Capacity

|

5N- 2000 N

|

|

2.

|

Maximum Temperature

|

1000 oC

|

|

3.

|

Voltage:

|

220 V

|

|

4.

|

Frequency

|

1-70 Hz

|

|

|

|

Test modules

1. Fretting Drive:

- Looad 5N to 2000N,

- Upto 70hz/500Hz, Dry &Lubricated Sliding

|

|

|

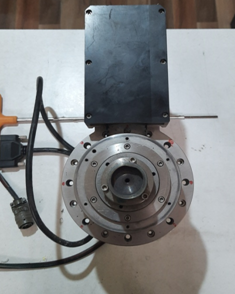

2. Rotatary Drive:

|

|

|

3. Heat temperature reciprocating Drive:

- High Temperature Tribology (up to 1000oC)

|

|

|

Engine Tribometer with Tribocorrosion

Rtec instruments - MFT-5000

Short Description:

- Stroke Control from 5 microns, High Torque Motors, 45Nm @ 1000RPM, High-Frequency Capacitive and Piezo Sensors, In-line Confocal + Interferometer Profilometer, Widest Environmental Range -120 to 1200C, Voice Coil and Flexure Based actuators

|

|

|

Test Modules

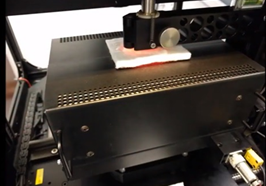

Reciprocating drive:-

- Linear reciprocating tribometer wear, pin on plate etc. up to 80Hz

- Stroke 0.1mm to 30mm

|

|

|

Long Stroke Reciprocating:-

- 40mm at 40Hz. test piston ring cylinder liner, engines, compressors etc.

|

|

|

High temperature Reciprocating Drive

- High Temperature Tribology (up to 1200C)

|

|

|

. Corrosion Testing:

|

|

|

Nano-Tribometer

For measuring Friction & Wear Characteristics of Nano Surfaces & Coatings

Short Description:

- Load:0.1mN to 1N, Reciprocating Sliding, Rotary, Ball diameter 1.5 to 2mm, Pin diameter 1.5 to 2mm, PoD, BoD

|

|

|

MICRO HARDNESS TESTER

Short Description:

- Large stand: 1500mm × 750mm x 825mm (UN-STAND/965), suitable for Vickers,Knoop, Micro-Vickers and automated systems (PC and video systems), 100% retractable drawer, bearing guidance, max 10g-3000g load. Rubber anti slip bottom, Lockable cabinet, 300mm high, Adjustable feet, (+/- 50mm height adjustable to reach ergonomic working position)

|

|

|

TRIVECTOR ANALYZER

Short Description:

- Sample Volume: 50 mL (2 oz.), Solvents/Reagents: lamp oil, Ambient Operating Temperature:15-30C (59°F to 86°F), Maintain temperature constant within +/- 3C (5°F) for rated performance, Storage Temperature:5-35C (41°F to 95°F)

|

|

|

3D Profilometer with AFM(Rtec)

Short Description:

- 3D Profilometer with interferometer radiation, AFM arrangements, Surface Roughness & texture analysis, wear volume analysis, Stiteting software, 3D Profile

|

|

|

Four Ball Tester

Short Description:

- Anti-friction,Anti-wear & EP additive Testing Facility, EP and WP test in single instrument, PC based machine control and data acquisition, Compare upto four test results in one screen, Image acquisition system, Automated loading, Inbuilt storage for accessories tools and samples (dead weight loading option only).

|

|

|

Optical Microscope

Short Description:

- LEICA DM 6000M, Motorized Focus Drive (15nm resolution), Automated contrast manager and illumination manager, Leica Smart Move, Six programmable function keys, Leica Smart touch, Six fold objective Turrent,5x-100x, C-mount adapter 0.55x, High definition live image 1920x1080p

Software

- LAS Image Analysis, Leica Grain Expert, Leica Cast iron Expert,Leica thickness Expert

|

|

|

SINTERING FURNACE

Short Description:

- Type-II super floor model for continuous use 80mm×450mm (standard model)400V/2Ph+N 6.3KW, Manual gas control unit with all accessories, Furnace body covered by stainless steel, TMP along with rotary vane pump with gage of 10-5mm Hg etc, Tube inside TC type-S with digital time indicators, RS232 Interface with operating software for temperature control with graphical display and gas supply system,Temperature:1900oC, Controlled Atmosphere Sintering

|

|

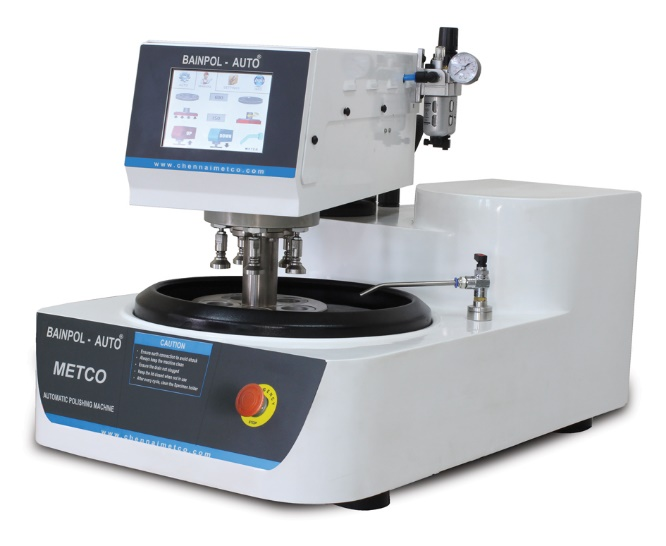

Automatic Polishing Machine

Short Description:

- Variable Speed 50- 600 RPM, 8” / 10"/ 12" Single Aluminum Disc, Hold up to 5 Moulds (1 ¼” standard), 1 HP High torque AC Motor, ¼ Hp Independent Polishing Head Motor, Polisher Head Variable Speed: 50 to 200 RPM, Electronic Control with LC – Display with Digital Timer, Variable force: 1 to 4 bar,With Interchangeable 1¼”, 1½” 2" Mould sizes, Single Pressure Specimen loading, Pneumatically applied, Multiple Moulds Design (1 ¼" standard), Single Pressure Specimen loading, Pneumatically applied, Pneumatically applied,Holding Band, Holding Ring, Power Supply: 230V / 50Hz (Single Phase + Neutral + Earth), Size:900 X 500 X 650 mm (L x W x H)

|

|

|

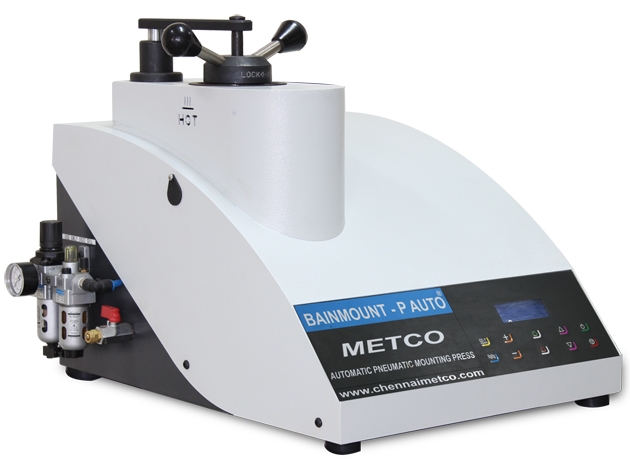

Automatic Pneumatic Mounting Press

Short Description:

To mount the sample in a plastic mould for convenient preparation

- Easy mould change 1 1/4", 1 1/2"dia and 2"dia, Heater 1200 Watts, Water cooling system, 1 Dimension: 490 X 620 X 520 mm

|

|

|

|